Company

Sewing Technology is a contract manufacturer of cut and sew products, primarily for the aerospace and defense markets. The company was founded in 1993 and was a woman-owned enterprise until 2015 when it was acquired by the current ownership. At that time Sewing Technology had sales of about $1.5 million and employed 14 people, including shop floor and office personnel.

Situation

Shortly after the ownership change, the company needed to execute on a contract from the U.S. Navy to supply 5,000 helmet covers per month over the next several years. Although this represented a huge sales opportunity, there was an issue in meeting the monthly demand, as seen in an immediate production backlog. This situation was also exacerbated by the limited availability of trained sewers in the area. It was also diffi cult to realize acceptable profi tability on a low margin product.

Solution

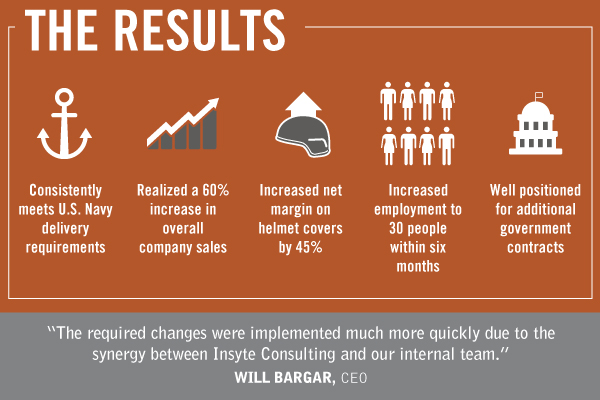

Insyte Consulting was engaged to help Sewing Technology address these issues. The application of Lean Manufacturing concepts helped the company signifi cantly increase throughput, meet on-time delivery requirements and improve overall profi tability. Key staff members were given a Lean Manufacturing overview that provided a foundation for the planned changes. The next step was to determine the required TAKT time which led to a review of work sequence, task times and balanced workflow. Based on these analyses, Standardized Work was introduced into the work area and Cellular Layout was designed to facilitate production flow. Visual Controls and guidelines were also introduced once the changes were made for effective cell operation. Purchasing and finished goods stocking methodologies were coordinated with cell operations. Metrics were also established so that the company could monitor ongoing performance.