Company

Mod-Pac Corporation is a high value-added, on-demand print services manufacturer; converting raw paper rolls into products in three categories: custom folding cartons, stock folding cartons and personalized print services. Their reputation among their customers is one of quick turnaround of custom items.

Situation

Mod-Pac warehouse operations are contained in a series of connected structures, separated by type of material stored within: raw material, corrugated, stock boxes and finished goods. As with many companies, Mod-Pac’s inventory has expanded to their storage capacity. This disjointed expansion has led to a situation in which the inventory is not as effective and consequently a warehouse operation that is not as efficient as it could be.

Solution

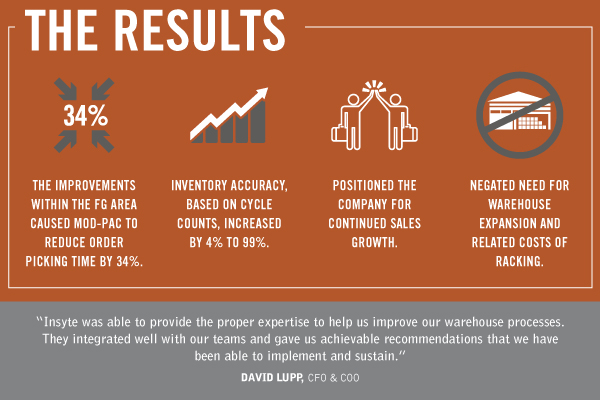

Insyte and selected Mod-Pac personnel assessed the current situation through observations, review of historical data, and discussions with warehouse and supporting personnel. A series of short- and long-term recommendations for each of the material categories were developed and discussed with Mod-Pac management. Mod-Pac management evaluated and prioritized the recommendations and started initiatives within each of the storage areas. Raw Material & Corrugated: Located high volume material close to the first processing step—reduced material handling time and distance traveled. Stock Boxes: Replaced pallet rack with flow rack for selected SKUs—decreased order picking time. Finished Goods: Removed double deep racks, rearranged remaining racking, established visual floor locations for high and medium volume product—increased inventory accuracy, reduced put-away and pulling time and decreased time of cycle counting. Relocated removed racking into separate area to increase storage capacity.